This training course provides guided wave inspectors with knowledge and hands-on experience with basic guided wave theory, operation of the MRUT scanner hardware and software, data collection procedures, and basic data analysis for basic scan configurations. The course comprises lectures, in-class data review, hands-on data collection, and independent data review. The course is approximately 1/3 in-class and 2/3 hands-on and data review. The course concludes with a written examination and practical examination.

Objectives

Successful graduates of this course should:

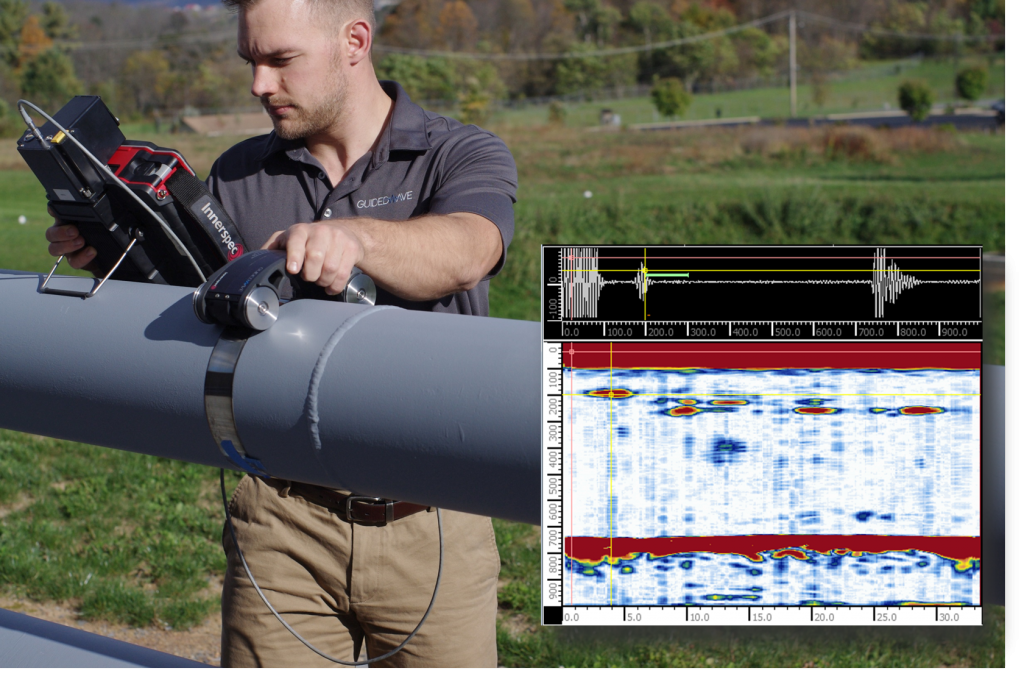

- have a basic understanding of guided waves in plates and the fundamentals of how the MRUT guided wave scanner system works

- be able to setup and connect the MRUT probe and PowerBox H hardware, carry out a system calibration and data quality check, and disassemble the system

- be able to navigate the PowerBox H MRUT software to set up jobs, collect data, and analyze data

- be able to carry out preliminary analyses of MRUT guided wave B-scan data on basic configurations, including straight sections of pipe sections, plates, and shells with minor curvature in the direction of wave propagation

- collect and interpret B-scans and A-scans, including SAFT-processed data

- understand the basic capabilities and limitations of the technology

Course Topics

- Fundamentals

- Introduction to guided waves for NDT

- Common applications for MRUT

- MRUT in the framework of a pipeline integrity management program

- The MRUT system

- Operation and assembly of the MRUT scanner probe

- Navigation and operation of the software

- Manufacturer-recommended inspection procedure

- Guided Wave Inspection Theory and Concepts

- Fundamentals of waves

- Bulk wave ultrasound and ultrasonic testing (UT)

- Basic guided wave theory

- Theory of guided waves in plates and shells

- B-scanning and SAFT processing

- Example MRUT applications

- Preliminary Guided Wave Data Analysis

- Creating sketches and recording pipe/plate information

- Recognizing data quality

- Interpreting the frequency sweep calibration data

- Generating and interpreting B-scans scans

- Utilizing SAFT processing for B-scans

- Identifying known reflectors such as welds, supports, and targets

- Identifying phantom indications

Scope

This course is intended to provide students with a basic understanding of medium-range guided wave applications in pipes and plates, to provide them with the knowledge and tools to follow an inspection procedure to collect high-quality medium-range guided wave data on basic pipe and plate configurations, to perform a preliminary analysis of data from these structures, and to provide them with a knowledge of the functionality and operation of the MRUT probe, the PowerBox H hardware, and the MRUT software. Basic pipes are considered to be generally straight sections of pipe or plates and shells with minor curvature in the direction of wave propagation.