Guided waves in plates rely on reflections from the upper and lower surfaces of the plates to propagate long distances in the plate parallel to these surfaces. Therefore, the thickness of the plate and the material of which it is constructed will determine the characteristics of the guided waves that it may support. Guided waves may exist in nearly any plate or shell structure in which the wavelength of the wave is greater than or on the order of the thickness of the plate. Thus, thinner plates may support guided waves with higher frequencies than thicker plates. In fact, one of the interesting characteristics of guided waves in plates is that the wave mechanics are based solely on the relationship between the thickness of the plate and the frequency of the waves.

In other words, a guided wave mode propagating in a 1”-thick steel plate at 100 kHz is physically equivalent to the same guided wave mode propagating in a 0.5”-thick steel plate at 200 kHz, because the ratio of the wavelength of the guided wave to the thickness of the plate are identical. One way to think about this is that the guided waves “experience” the waveguide in which they travel in terms of their wavelength. If they have a large wavelength (e.g. at low frequencies), then a plate with a thickness smaller than that wavelength will “appear” to be thin to the guided wave. Conversely, if the same guided wave has a smaller wavelength (e.g. at higher frequencies), then that same plate may “appear” to be thick.

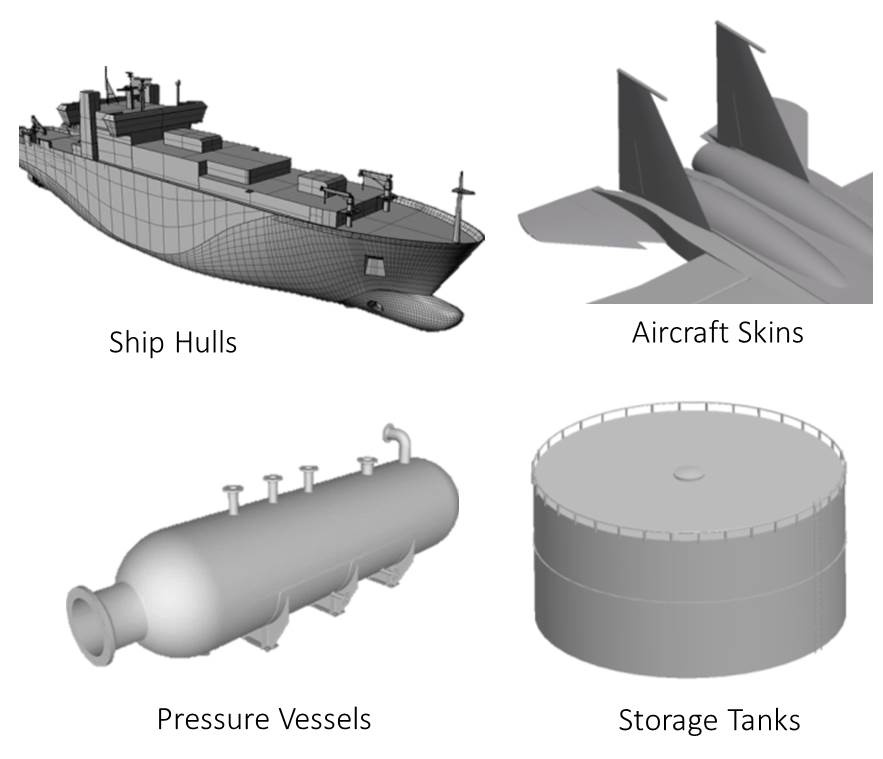

Guided waves can also propagate through plates and shells with moderate degrees of local curvature without being negatively affected. Generally, the higher the frequency of the guided wave, the less it will be affected by this curvature. Again, one can think about this in terms of the “experience” of the guided wave in the structure through which it is propagating. If the guided wave has a small wavelength relative to the curvature of the structure, then it may not notice this curvature, just as humans do not notice the curvature of the Earth. On the other hand, if the guided wave has a much larger wavelength, that same curvature may appear to be more severe, just as a human standing on a large ball would notice its curvature. This property of guided waves in plates can be exploited with any of the transducers offered by Guidedwave, such as the MRUT scanner, the magnetostrictive NDT/SHM transducers, guided wave angle beam probes, and even phased array probes to inspect curved plates and shells such as pressure vessels, containment vessels, ship hulls, aircraft panels, and more.

Guided waves in homogeneous isotropic plates are generally categorized into two classes:

- Lamb waves

- Shear horizontal (SH) waves

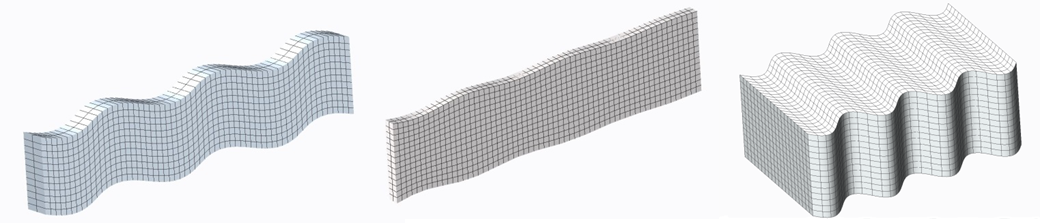

The fundamental difference between these two types of guided waves in plates lies in their distinct vibration characteristics. As Lamb waves propagate along a plate or shell, they vibrate out-of-plane (i.e. perpendicular to the surfaces of the plate) and in-plane parallel to their propagation direction. While these vibration characteristics vary between the different Lamb wave modes and also vary with frequency, they can generally be classified into two types: A (anti-symmetric) Lamb wave modes and S (symmetric) Lamb wave modes. The A modes are similar to flexural waves (think about holding a thin of metal by one edge and flapping it up and down to send ripples along the plate). The S modes are similar to compressional waves (think about striking a thick sheet of metal along its edges to send a compressional wave through the plate). Guidedwave offers a range of angle beam probes to generate and receive Lamb waves in plates. By tuning the angle of the wedge according to Snell’s Law, particular guided wave modes can be selectively excited and detected using these transducers. Variable-angle wedges offer the opportunity to tune this angle on the fly or to conduct guided wave research. Lamb waves can also be generated and received with specially-designed magnetostrictive transducers.

On the other hand, shear horizontal (SH) waves have neither out-of-plane vibrations nor in-plane vibrations parallel to the direction in which they propagate, but rather are solely comprised of shearing vibrations that are perpendicular to both the surfaces of the place and the direction in which the waves propagate. Since low-viscosity fluids don’t support shearing vibrations, the unique in-plane shear characteristic of SH waves makes them suitable for applications in which the plate or shell is in contact with a low-viscosity fluid, such as ship hulls, plates exposed to rain water, pressure vessels, etc. While Lamb wave energy will leak into and interact with such fluids, SH waves are completely unaffected by them. An additional benefit of the fundamental shear horizontal mode in plates, also known as the SH0 mode, is that it is purely non-dispersive, which means that it propagates at the same velocity in plates of any thickness at any frequency; in fact, it propagates at the transverse (shear) bulk wave velocity in the material. Also notice from the SH wave dispersion curve that at lower frequencies, only one SH wave mode exists, which means there is no confusion caused by unwanted guided wave modes propagating in the plate at different velocities. These characteristics can make systems that utilize the SH0 mode in plates and shells simple to use and robust across a wide range of structures.

These reasons, among others, are why Guidedwave utilizes SH wave elements in our phased array system for plates and shells and our general SHM tomography system. Guidedwave offers additional SH wave probes in many of our magnetostrictive transducers for NDT and SHM, both of which may be applied to plates, shells, and other structures.

Guided wave systems for plate and shell inspection can be developed to operate in a wide range of modalities depending on the application. Simple line-of-sight inspection can be done with angle beam probes (using Lamb waves) or magnetostrictive probes (using SH waves). A more advanced application of plate inspection is guided wave phased array, which rapidly and automatically creates radar-like images of the plate or shell structure. Long-term structural health monitoring using computed tomography is another advanced application of guided waves in plates.