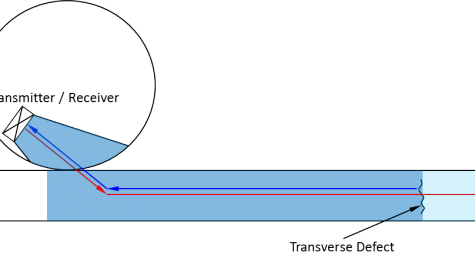

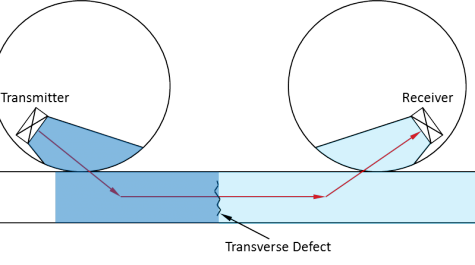

One of the most critical defects found in rail is the transverse defect, as they can lead to a rail break. Defects that develop in the transverse plane are normally internal in origin and not visible from the outside of the rail. Due to the fact that these defects are normal to the top of the head they are also difficult to detect with bulk wave ultrasound. Transverse defects also commonly occur under shelling which can make them more difficult to detect with bulk wave ultrasound. Guided waves traveling along the axis of the rail are traveling in the optimal direction to reflect off of and detect transverse defects as they are traveling normal to the defect plane. Guided waves also have the ability to propagate under shelling defects and still be sensitive to transverse defects. Guidedwave has patented technology which uses a guided wave wheel probe to detect transverse defects in both the head and the base of rail. Guidedwave is pleased to be working in conjunction with Olympus Scientific Solutions Americas and Nordco on this technology.

Advantages

- Builds on existing wheel probe technology

- Can detect defects under shelling

- Can detect defects over a large range of distances

- Can detect defects that are normal to the surface more easily than bulk wave ultrasound