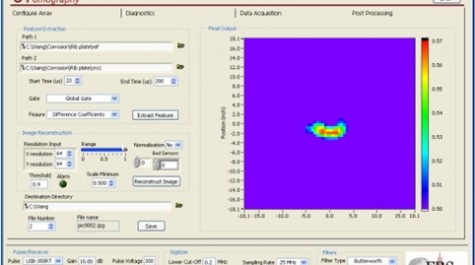

UTOMO technology was developed specifically for large-area structural health monitoring (SHM) of aircraft components to eliminate the need for expensive, time-consuming, localized inspections. The UTOMO technology takes advantage of the long-range propagation characteristics of ultrasonic guided waves in conjunction with highly-sensitive computed tomography (CT) techniques to provide accurate, large-area damage detection capability. This system is operated in conjunction with custom software and the Olympus UltraWave platform or a multiplexed pulser/receiver unit. An overview of the technology is as follows:

- A sparse guided wave sensor array is permanently attached to the surface of the structure

- Reference guided wave data is acquired by transmitting and receiving guided waves with every possible sensor combination in the array

- Guided wave data is reacquired at predetermined time intervals

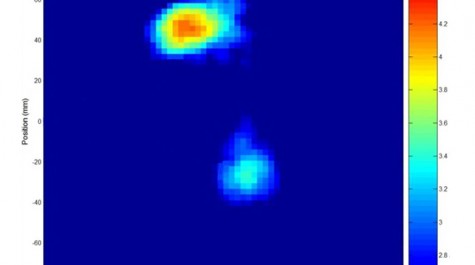

- Computed tomography (CT) images are constructed by comparing the reference data to the reacquired data

- Damage location, area, and severity is accurately mapped in the CT image